Continuous Emissions Monitoring Systems (CEMS) are specialized systems designed to continuously monitor and record emissions of air pollutants from industrial sources in real-time. These systems are crucial for tracking emissions of pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), carbon monoxide (CO), volatile organic compounds (VOCs), and particulate matter (PM) from industrial processes and facilities.

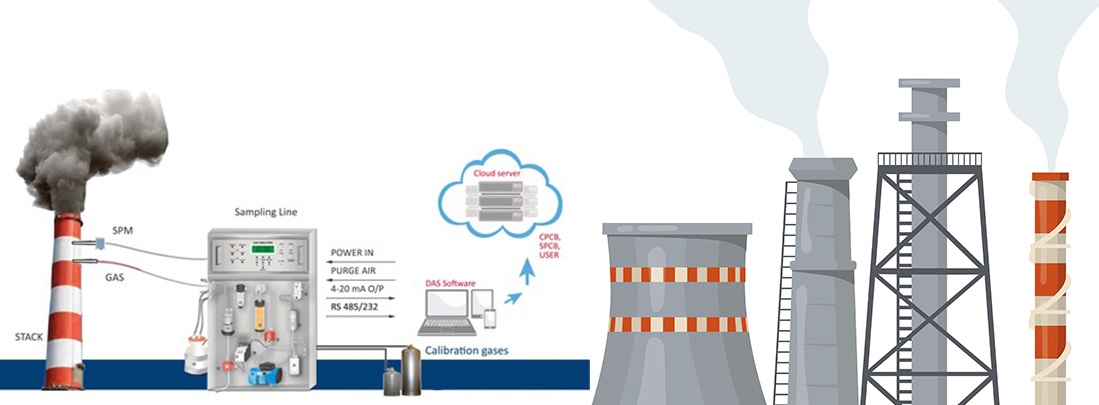

CEMS typically consist of various components, including emission sensors, sample probes, data acquisition systems, and reporting software. These components work together to continuously measure and analyze emissions data from industrial stacks, ducts, or process streams. The data collected by CEMS is then used to monitor compliance with environmental regulations, assess environmental impacts, and optimize process efficiency.

1. Gas Analyzers: Measure concentrations of specific pollutants in emissions using various techniques such as infrared spectroscopy, gas chromatography, and laser-based technologies.

2. Sample Probes: Extract representative samples of emissions from the source for analysis by the gas analyzers.

3. Data Acquisition Systems: Collect, process, and store emissions data in real-time, allowing for continuous monitoring and reporting.

4. Calibration Systems: Ensure the accuracy and reliability of CEMS measurements through regular calibration and maintenance.

5. Reporting Software: Generate comprehensive reports and data summaries for regulatory compliance, internal analysis, and stakeholder communication.

1. Regulatory Compliance: CEMS help industries comply with environmental regulations by providing accurate and reliable emissions data for regulatory reporting and monitoring.

2. Environmental Protection: By continuously monitoring emissions, CEMS help identify and mitigate sources of pollution, protecting air quality and public health.

3. Process Optimization: CEMS data can be used to optimize industrial processes, improve energy efficiency, and reduce emissions, leading to cost savings and environmental benefits.

4. Data Transparency: CEMS provide transparent and verifiable emissions data, enhancing accountability and trust with regulators, stakeholders, and the public.

Nilofer Gulf offers comprehensive CEMS solutions tailored to the specific needs of our clients. With our technical expertise, industry experience, and commitment to quality, we provide turnkey CEMS services, including system design, installation, calibration, maintenance, and data management. Our team ensures that CEMS are installed and operated in compliance with regulatory requirements, allowing clients to meet their environmental obligations with confidence and efficiency. Partner with Nilofer Gulf for reliable and accurate CEMS solutions that support environmental stewardship and regulatory compliance.

Please Subscribe our news letter and and get update.